Linear Units

If you have any query related our products ... We are available

Contact Us

XL 85 B and Linear Units are with toothed belt drive and compact dimensions provide high performance features such as, high speed, good accuracy and repeatability. Excellent price - performance ratio and quick delivery time are ensured. The compact precision extruded aluminum profile from 6063AL with integrated zero backlash ball rail guide system, allows high speed. in the profile slot driving polyurethane timing belt protects all the parts in the profile from dust, for extra protection C cover is also provided. The aluminum profile includes T- slot for fixing the linear unit & for attaching Sensors, Switches, Reed Switches etc..

XL 85 /100 Linear Unit described with precision ball screw drive integrated guide rail & compact dimensions. They provide high performance features such as high speed, good accuracy and repeatability. They can easily be combined to multi axis systems. In the linear unit XL 85/100 precision ball screw with reduced backlash of ball nut is used. Dust and contamination protection cover is provided for 1500mm stroke length linear unit. The Aluminum profile includes T- slots for fixing the linear unit as per users suitability. Also these T- slots can be used for Limit switches, Sensors, Reed switches fitment.

| Parameters | XL 85-B | Xl 100- B | XL 85 | Xl 100 |

|---|---|---|---|---|

| Stroke Length Max. (mm) | 4000 | 5000 | 1500 | 1500 |

| Linear Speed Min.(m/s) | 2 | 2 | 0.4 | 0.4 |

| Acceleration Max. (m / s2 ) | 20 | 20 | 8 | 8 |

| Repeatability (+-mm) | 0.05 to 0.1 | 0.1 | 0.03 to 0.05 | 0.03 to 0.05 |

| I/P Speed Max. (rpm) | 600 | 1200 | 3000 | 3000 |

| Operation Temp. Limits (Degree C) | 0 to 70 | -5 to 70 | -5 to 70 | -5 to 70 |

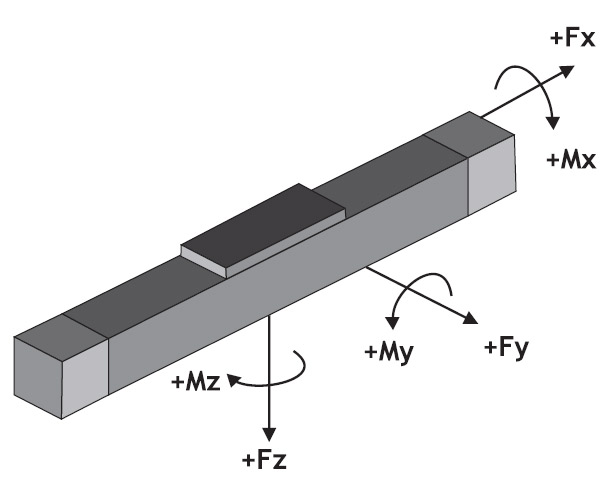

| Dynamic Load (Fx) Max. | 1500 | 1200 | 2500 | 3500 |

| Dynamic Load (Fy) Max. | 3000 / 5000 | 4000 | 1445 | 2500 |

| Dynamic Load (Fz) Max. | 3000/5000 | 4000 | 1445 | 2500 |

| Dynamic Load Torque (Mx) Max. | 75 | 200 | 49 | 117 |

| Dynamic Load Torque (My) Max. | 150 | 450 | 85 | 230 |

| Dynamic Load Torque (Mz) Max. | 150 | 450 | 85 | 230 |

| Pulley Diameter (mm) | 55 | 55 | — | — |

| Stroke/ Shaft Revolution (mm) | 172 | 172 | — | — |

| Screw Diameter (mm) | — | — | 16 / 20 | 16 / 20 |

| Screw Lead (P) (mm) | — | — | 5 / 10 | 5 / 10 |

| Profile Size (mm) | 85 | 104 | 85 | 104 |

| Type of Belt | T5 / T10 | T5 / T10 | — | — |

If you have any query related our products ... We are available

Contact Us